Investigating the desired repellence and erosion resistance

03 August 2022

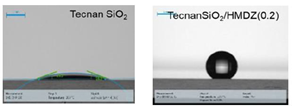

Based on the commercially available systems, the selection of the wind turbine blade coating for trials was undertaken. In order to achieve the desired repellence (superhydrophobicity) and erosion resistance, TWI has incorporated functional additives into the selected coating matrix. All selected additives were based on materials which have previously been demonstrated to be platforms for superhydrophobic surfaces.

These additives are inorganic metal oxides that are capable of surface functionalisation to enable their native hydrophilic surfaces to be transformed into exhibiting hydrophobic behaviour. The key additives explored are:

Stöber derived TWI silica

Metal oxides (TECNAN’s silica manufactured using pyrogenic methods and commercially available pyrogenic silica Aerosil 200)

The mentioned functionalized silicas were incorporated into PU model matrix system in a various combinations and various loading levels. TWI have undertaken wettability, abrasion, adhesion and chemical resistance tests, whereas EIRE took care of rain erosion examination. INL have been given coated samples to perform long-term weatherability study.

All developed coatings improved the repellent characteristics of commercial model matrix system. Satisfactory results were also obtained from adhesion, abrasion and chemical durability tests. Nevertheless, the erosion resistance of those coatings was still not reaching target values and therefore, second generation coatings were developed.

Next steps

Further minor coating modifications will be done – addition of second functionalization might be necessary in order to bind silica particles with model matrix system via covalent bonding and thus, to increase the resistance towards rain erosion. The result from the rain erosion study suggested that developed coatings were too hard and this is not beneficial in terms of providing the resistance towards flowing water. Therefore, silica microparticles won’t be functionalized at all, to prevent and increased hardness caused from bonding together or to the matrix.